Cleveland Cliffs Tilden Mine – HPGR Installation

Project: High Pressure Grinding Roll Installation

Owner: Cleveland Cliffs

Scope of Work: A new High Pressure Grinding Roll (HPGR) installed at the Tilden Mine was a strategic initiative by Cleveland-Cliffs to reduce equipment maintenance, increase throughput and increase energy efficiency. The goal: reducing production costs and maintaining market competitiveness. Lakehead was hired to install the HPGR on the discharge end of Tilden’s intermediate crusher circuit, allowing the HPGR to further process the product before recycling the material into the primary milling circuit.

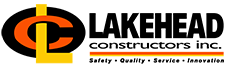

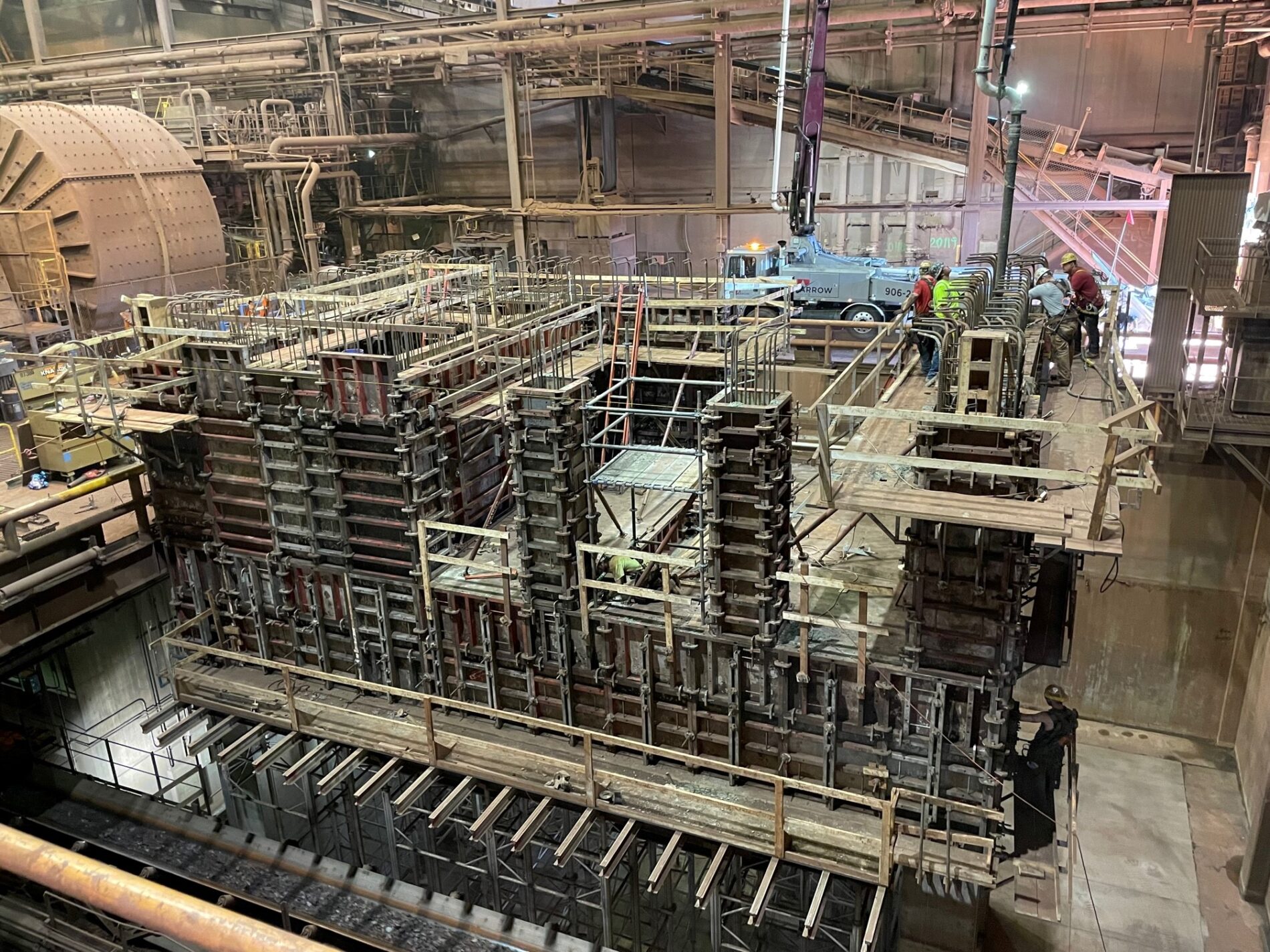

Inside the plant’s concentrator building, concrete crews began forming massive concrete footings and foundations for the HPGR using Meva form systems, resulting in an 800-cubic-yard reinforced concrete foundation that measures 24’ x 42’ x 36” thick and 53’ tall.

Once the foundation was complete, the project team moved into the mechanical installation phase which included:

- Installation of HPGR machine, including full equipment assembly, feed hopper, process water, lubrication, air piping and electrical

- Installation of (4 each) belt conveyors including transfer chutes, travel ways, and support structures

- Modification to existing crushed product feed bin

- Erection of structural steel including stair tower, HPGR maintenance platform, travel ways, and dust collector platforms

- Installation of (5 each) dust collection systems, including compressed air system, piping, and electrical equipment

- Electrical includes control equipment, wiring, electrical disconnects and MCC equipment and MCC modifications

Self-performed: Civil, structural and mechanical installation scopes including concrete, steel erection, equipment and conveyor installation, piping, crane support and heavy lifting.